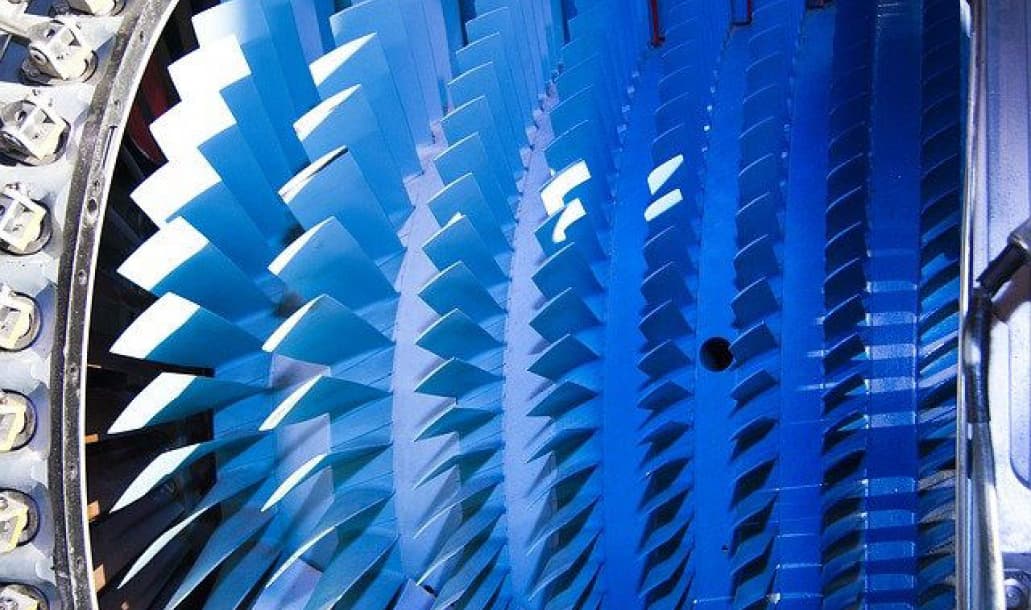

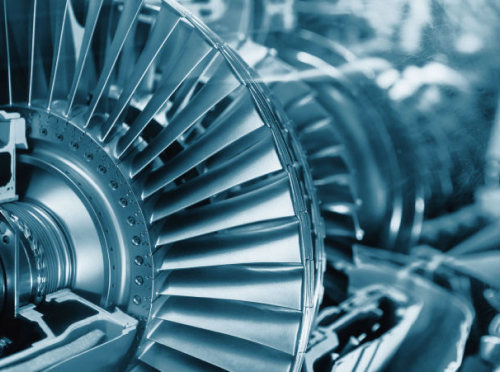

Repairable Alloys for Aerospace

Aerospace Superalloys We Work With

At MicroWeld Engineering, we understand that your components are critical to your business, and downtime can be costly. That's why we offer a comprehensive range of welding and repair services for a variety of repairable alloys.

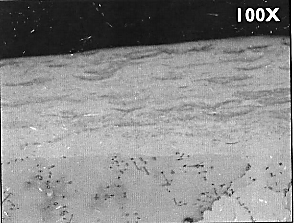

Our team of expert technicians specializes in restoring components using MicroMIG™, an innovative, fully bonded fusion weld process that excels in welding unweldable materials, joining dissimilar metals, and enhancing wear resistance.

We offer welding repairs for a wide range of materials, including nickel and cobalt-based superalloys, magnesium alloys, stainless steels, and hardface and carbide alloys. Our goal is to help our clients minimize downtime and reduce costs by offering high-quality welding repairs for their repairable alloys.

Frequently Repaired Superalloys

Explore our frequently repaired superalloys below. If your specialized metal isn't listed, we invite you to contact us for a complimentary quote to discuss your unique requirements and discover the best solution for your needs.

Request a Quote

Nickel Based Superalloys

625, 713, 713C, 713LC, 718, 738, 792

41, 80, 88, and 108

C, X, W

188, 500, 720

188, 230, 242

Cobalt Based Superalloys

12,20, 31

Hardface and Carbide Superalloys

Unlock Precision: Request Your Free Quote Today!

Our Commitment To Quality