About MicroWeld Engineering

Your Trusted Aerospace Welding Solution

Founded in 1988 and located in Worthington, Ohio, we are proud to serve aerospace suppliers and jet engine manufacturers worldwide. With our AS9100-certified Business Management System, we are committed to delivering impeccable quality that sets us apart in the industry.

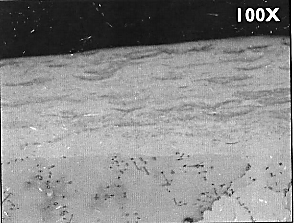

Meeting the Challenges of Unweldable Alloys

Driven by our close partnerships with aerospace manufacturers, we recognized a pressing challenge - welding alloys that were previously deemed unweldable. Conventional welding processes resulted in micro-cracks, also known as liquation, in these high-temperature alloys used in today's advanced jet engines. In response, we developed our groundbreaking MicroMIG™ welding process in 1990.

MicroMIG™: Revolutionizing Welding in Aerospace

Since its inception, MicroMIG™ has revolutionized the repair of turbine engine components, becoming a trusted solution for military and commercial engines worldwide. Our continual investment in research and development has enabled us to enhance the MicroMIG™ process, making it even more versatile and effective. We have developed unique methods and tooling that allow us to weld even the most intricate parts on complex gas turbine engine components.

Continued Innovation and Commitment to Quality

At MicroWeld Engineering, we understand the necessity of staying ahead in a rapidly changing industry. Through independent and collaborative studies, we continue to innovate and improve our welding techniques, ensuring we meet the evolving needs of our customers. We are dedicated to providing reliable and cutting-edge solutions that surpass industry standards and maintain our position as a trusted leader in aerospace welding.

Contact us today to experience the superior quality and expertise that have made us the preferred choice for aerospace welding solutions. Let's push the boundaries of what is possible in aerospace manufacturing.

Interested in a Career at MicroWeld?

Our Commitment To Quality