Aerospace Precision Welding

Restoring Unweldable Ni-Based Super Alloys

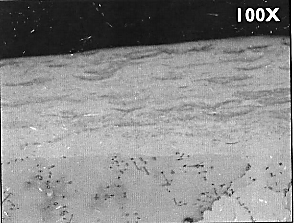

At MicroWeld Engineering, we recognize that quality is not just a requirement - it's a necessity in the aerospace industry. That's why we've developed the MicroMIG™ process, a precision welding solution that can restore even the most unweldable Ni-based superalloys in high-temperature engine zones to their original, flawless condition. Our micro-welds are free from heat-affected zones (HAZ) or micro-cracks, ensuring exceptional performance and safety.

Exceeding Casting Limitations

MicroMIG™'s fully bonded fusion weld process empowers customers to exceed their casting limitations. Whether rectifying design flaws, correcting part dimensions or casting imperfections, our process excels in welding unweldable materials, joining dissimilar metals, and enhancing wear resistance.

Trusted by Leading Aerospace Engine Manufacturers

Our track record speaks for itself. From prototype weld repairs on engine components to process optimization in production, we've been entrusted with a wide range of projects by a diverse clientele, including government and private entities. Today, some of the world's most renowned aerospace engine manufacturers rely on us for our MicroMIG™ services.

Sustainability and Environmental Responsibility

By leveraging the MicroMIG™ process, our customers can revive new castings that would have otherwise been scrapped, thereby significantly reducing energy costs, pollution, and time investments. At MicroWeld Engineering, we are committed to sustainability and environmental responsibility. Our dedication to minimizing waste and improving efficiency resonates in our work, benefitting our customers and the environment. As manufacturers, each of us plays a vital role in stewarding the earth entrusted to us

Contact us today to learn more about how MicroMIG™ can benefit your specific welding needs.

Request Your Free Quote Today!

Our Commitment To Quality