The MicroMIG™ Proprietary

Repair & Development Process

Utilizing the MicroMIG™ Proprietary Process

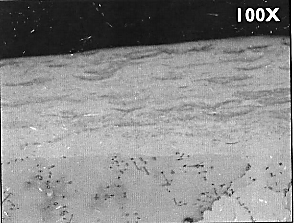

MicroMIG™ is a pulsed-arc micro-weld process that deposits a solid filler material on a metallic base material, resulting in a fused metallurgically bonded weld without distortions or observable HAZ (heat-affected zone). Our manual operation, combined with the use of inert gas to shield welds from contamination, ensures excellent results through the true metallurgical fusion of a weld filler material and the parent base material.

MicroMIG™ excels in producing microscopic conventional welds, with each weld pass measuring in thousandths of an inch. This precise approach allows us to scale down the homogenous weld layer thickness and minimize the heat-affected zone (HAZ) to millionths of an inch. As a result, we can successfully weld on previously unweldable alloys while maintaining the integrity of the base metal.

Discover the Advantages of MicroMIG™ Precision Welding

- No distortion: MicroMIG™'s low total heat input prevents distortion of machine-finished parts manufactured to tight tolerances, making it an ideal choice for repairing such components.

- Versatile welding: With MicroMIG™, we can weld different filler metals onto various base metals, allowing us to create wear-resistant coatings, improve corrosion resistance, and solve tough brazing applications.

- Proprietary technology: Our unique process leverages specific wire diameters, advanced pulsing techniques, and precise current and voltage control. As a result, we provide excellent weld quality and shorter turn-around times without selling equipment.

- Fused metallurgical bonded weld deposit: The MicroMIG™ process ensures a fused metallurgical bonded weld deposit with no observable HAZ or distortion of the base material. Our power supply and special welding torch utilize a pulsed arc to raise the temperature of the filler metal to the liquidus temperature, seamlessly bonding it to the base material.

At MicroWeld Engineering, we take pride in our commitment to delivering high-quality welding services. Our trademarked MicroMIG™ process sets us apart by providing reliable and durable welds without compromising the structural integrity of the base material.

Contact us today to learn more about how MicroMIG™ can benefit your specific welding needs.

Request Your Free Quote Today!

Our Commitment To Quality