MicroMIG™ Advanced Welding Technology

Our Proprietary Solution For Your Most Demanding Welding Applications

Repair Defects. Refine Development. Restore Quality Castings.

Repair Defects in "Unweldable Alloys"

The innovative MicroMIG™ process overcomes the limitations of conventional welding techniques for alloys that were once considered unweldable.

Learn More

Development is the Focus

The MicroMIG™ process is a valuable tool for development and prototyping, enabling customers to fine-tune their manufacturing process and optimize welding parameters.

Learn More

Restore Quality Castings

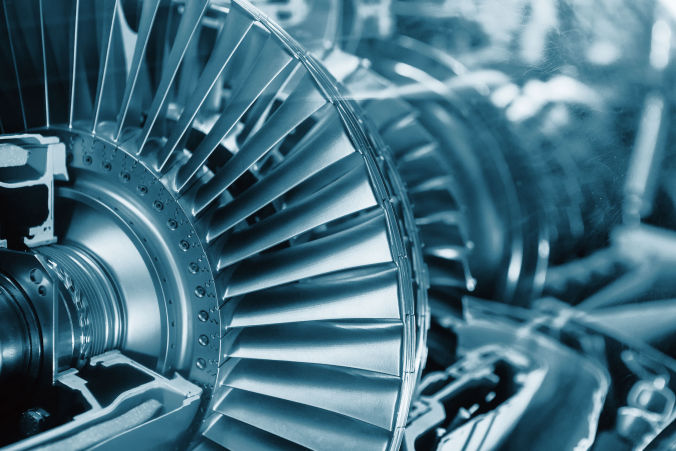

Jet engine manufacturers rely on the certified MicroMIG process to restore castings with an exceptional success rate exceeding 99.9%.

Learn MoreAerospace Precision Welding

Trusted by Leading

Aerospace Engine Manufacturers

The MicroMIG™ advanced welding technology salvages new castings labeled as scrap due to defects by restoring them to like-new condition. The results reduce manufacturing costs, environmental impact, and time investment.

Learn More

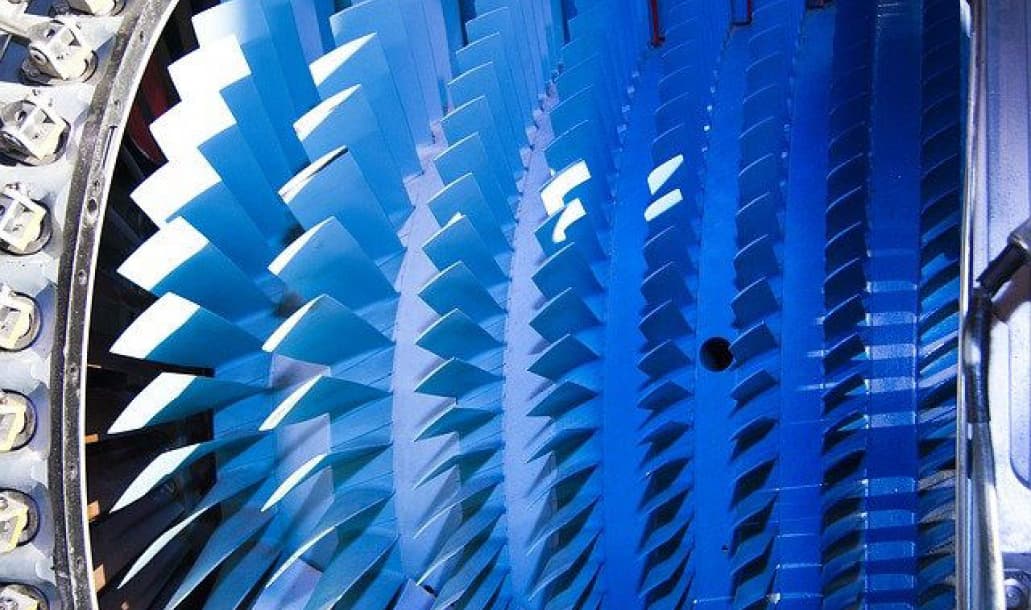

Repairable Alloys for Aerospace

We service a comprehensive list of manufactured alloys including:

- Nickel-Based Superalloys

- Cobalt-Based Superalloys

- Magnesium Alloys

- Stainless Steels

- Hardface and Carbide Alloys

WHY CHOOSE MICROWELD?

We have extensive experience.

Since 1988, we have provided advanced welding technologies primarily to some of the top aerospace suppliers, jet engine manufacturers and local customers specializing in unique markets. Our work has been utilized by both government and private entities from prototype weld repairs on engine components to process optimization in production. MicroMIG™ repaired parts have been flying in commercial aircraft since the early 1990s.

We have a full aerospace certified quality assurance program

Our Business Management System is AS9100 certified and has been since 2010. We provide the necessary quality documentation, travelers, shop routers, NIST traceability, inspections, and welder certs to meet the standards you demand.

The impeccable quality we hold ourselves to is the lifeblood of our company.

In the aerospace industry, quality is of the utmost importance. Our successful weld repair rate of over 99.9% speaks to the consistency and applicability of our process and standards.