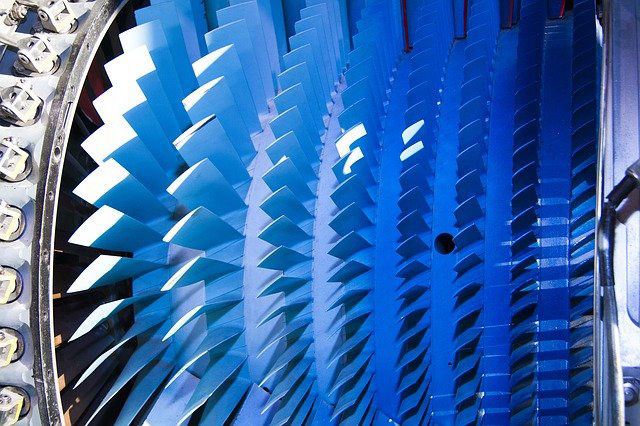

Repair Defects in "Unweldable Alloys"

The defining characteristic that makes an alloy weldable or not is it's tendency to exhibit liquation micro cracks in the heat affected zone from welding.

Finish Machined Components

If you

have a part that is finished, or should be finished,

but there are small surfaces that are undersized from

the machining operations.

Learn more...

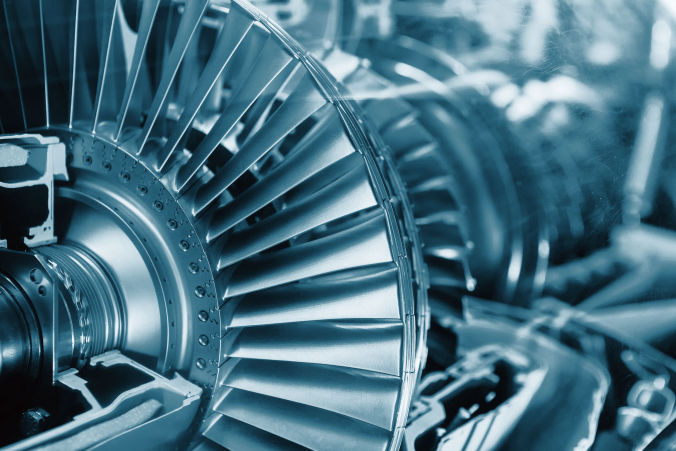

Restore Castings

With a

success rate of over 99.9%, restoring a casting with

the MicroMIG™ process is currently a certified

process for numerous jet engine

manufacturers.